Production and Customised Services

Quality Control Checks

Description :

In order for us to provide the best products to our customers, we implement multiple QC checks on all our products, such as:

Raw Materials Content Check

All our raw materials go through a 100% quality check using our In-House X-Ray Fluorescence Spectrometer to ensure the exact chemical content of each coil.

Material Dimension and Thickness Check

At each step of production, each product goes through a list of stringent quality control and standard verification including dimension, weight, and thickness measurement. This is to make sure each product being produced adheres to the standards being implemented.

Tube Dimension Check

After forming, our tubes goes through the tube dimension checkpoint where each tube is checked for its roundness (for round tubes) or dimensions and corner angles (for square / rectangular tubes). Tube straightness is also checked at this checkpoint.

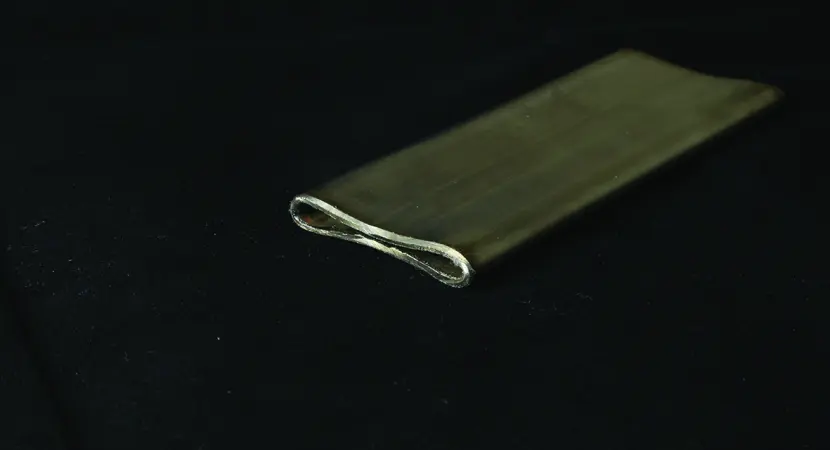

Welding Strength Check

To maintain high quality consistency of our products, the forming and welding aspects of our products are tested in accordance to ASTM / JIS / BS EN Standards which include:

Eddy Current Test for leak tightness, drift expanding and flattening tests

Surface Check

For our "Surface Priority" customers, we also implemented specular reflection gloss check on our products, and a surface roughness check to ensure maximum desired effect is obtain.

In addition to our standard checks, we also work with third party testing providers to do custom checks and certifications as required by our customers.